Why Choose Lipin's Square Knife Gate Valve

Lipin's expertise in valve manufacturing is exemplified in its Square Knife Gate Valves, designed for precision and reliability. Let’s delve into the reasons why Lipin's Square Knife Gate Valves are an optimal choice:

-

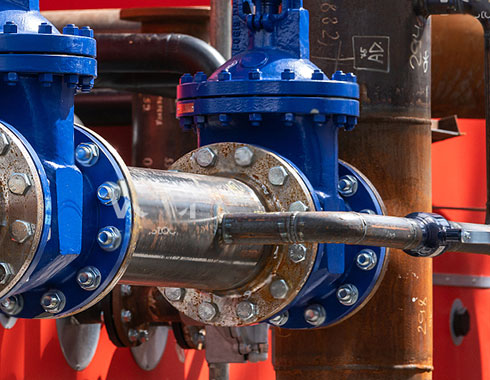

Seamless Flow Path

The through conduit design of these valves ensures a straight flow path, reducing turbulence and minimizing pressure drop, critical in systems requiring efficient flow management.

-

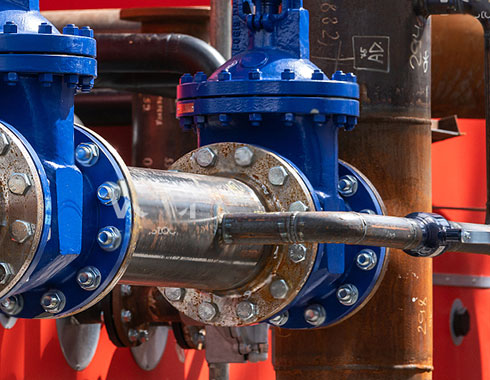

Material Selection

Lipin offers these valves in resilient carbon steel for general use, and in 316 stainless steel or duplex stainless steel for environments prone to corrosion.

-

Adaptability

Ideal for various industries, including oil and gas, mining, and wastewater management, these valves are versatile and reliable for a range of applications.

-

Standards Compliance

Adhering to ASME standards, these valves are constructed for durability and peak performance, ensuring long-term, safe operation.

-

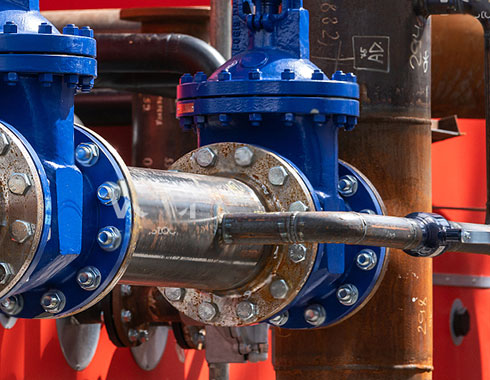

Customer Support

Lipin's commitment includes comprehensive support, focusing on a partnership approach for ongoing assistance and valve maintenance throughout its lifespan.